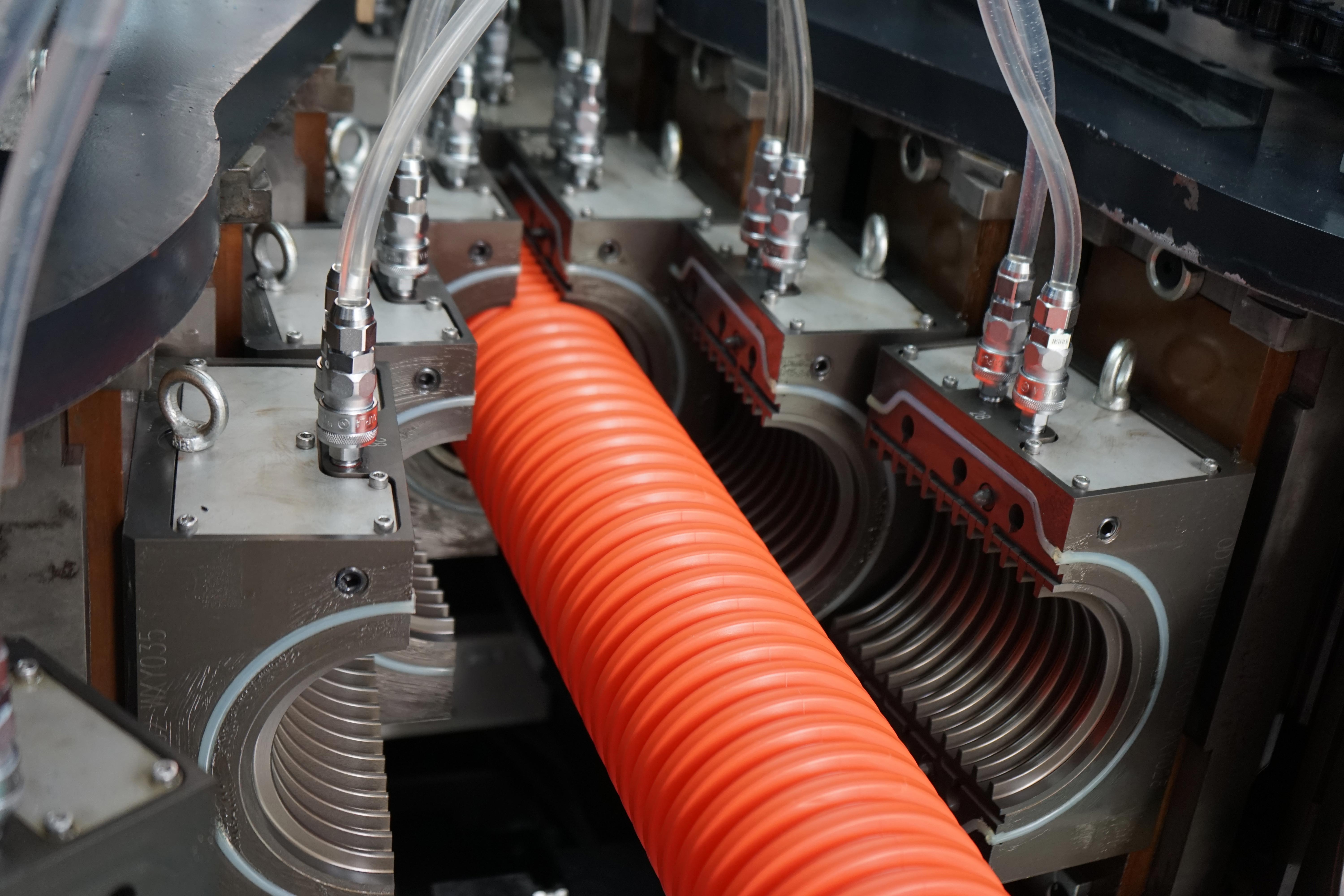

As your trusted global manufacturer specializing in corrugated pipe machine, we are committed to not only providing high-quality machinery but empowering you with knowledge to enhance the performance and extend the service life of your equipment.

Now, we delve into the crucial realm of maintenance and share a step-by-step guide on optimizing your corrugated pipe machine's functionality.

Step 1: Routine Inspections

Regularly inspect your corrugated pipe machine to identify any signs of wear, tear, or potential issues. Pay close attention to components such as rollers, blades, and heating elements. A routine inspection schedule will allow you to catch and locate minor problems before they escalate.

Step 2: Lubrication is Key

Proper lubrication is vital for the smooth operation of your corrugated pipe machine and increase their durability. Ensure that all moving parts, including bearings and gears, are adequately lubricated. Follow the recommendations for the type and frequency of lubrication to prevent friction and reduce wear.

Step 3: Cleanliness Matters

Keep your machine clean from debris, dust, and material residues. Regularly clean the corrugating rolls, cutting blades, and other essential components. A clean machine not only functions more efficiently but also prevents contaminants from causing premature wear.

Step 4: Temperature and Speed Control

Maintain control over temperature settings and machine speed. Operating your corrugated pipe machine within the recommended temperature range ensures optimal performance and minimizes the risk of overheating. Similarly, adhering to specified speed limits helps prevent unnecessary stress on components.

Step 5: Comprehensive Operating Training

Empower your operators with the knowledge they need to use the machine effectively. Provide comprehensive training on proper operating procedures, maintenance protocols, and troubleshooting techniques.

Step 6: Timely Replacements

Monitor the condition of consumable parts, such as blades and belts, and replace them promptly when necessary. Regularly replacing worn-out components prevents damage to other parts of the machine and ensures consistent output quality.

Step 7: Professional Servicing

Schedule professional servicing at regular intervals. Engage with our expert technicians to conduct thorough inspections and address any potential issues. Professional servicing goes a long way in preventing unexpected breakdowns and extending the overall lifespan of your corrugated pipe machine.

By following these step-by-step guidelines, you're not just maintaining your corrugated pipe machine; you're investing in its long-term performance and reliability.

At ZhongyunTech, we are dedicated to supporting you every step of the way, ensuring your success in the corrugated pipe industry.

Sign up for our bimonthly newsletter

Privacy Policy- I have read and I authorize the processing of my personal data