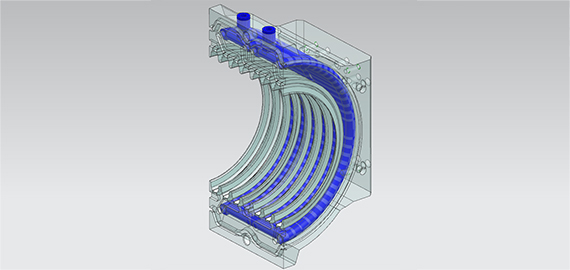

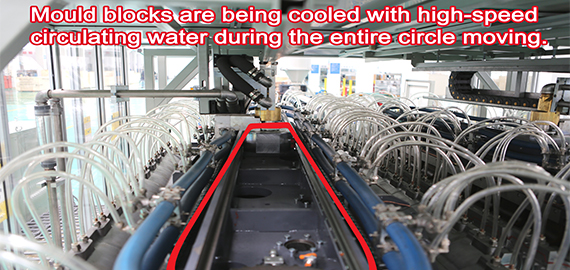

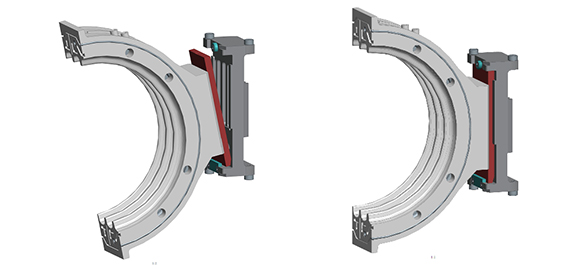

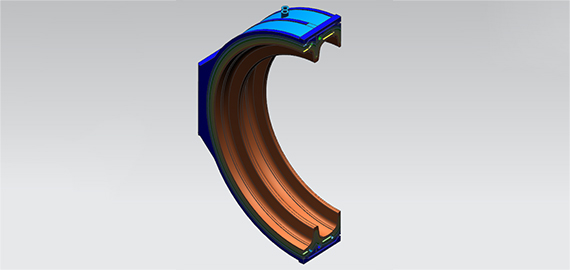

High-efficient cooling for mould blocks.

The mould blocks are cooled with pressure water cooling system continuously, water circulate in sealed channels with pressure to achieve higher cooling efficiency and higher production speed.

Full Time Cooling.

The mould blocks are continuously chilled by the cooling water throughout the whole running track.

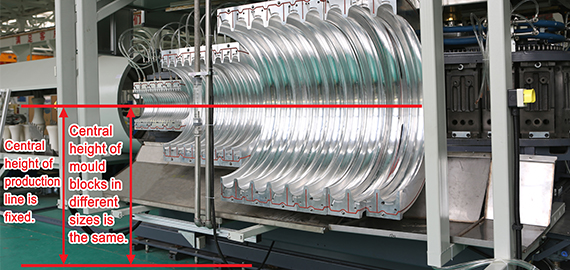

The mould blocks can be compatible between different models of production lines; it makes production organization more flexible.

Innovative rapid assembly of mould blocks simplifies the operation of changing mould blocks and greatly shortens the down time.

All new design of non-platform corrugator. Do not need to adjust the corrugator height when changing moulds for different sizes. Operation becomes easier and more efficient.

Mould block temperature control system helps to optimize the pipe quality both appearance and inside.

At ZhongyunTech, we care about the customers experience and service; we put great importance to collecting customers feedback. That is why we keep constant communication with our old customers by our service representatives.

15

Professional service engineers

8+

YearsMost of service engineers have over 10 years professional experience.

6000

m2Spare parts warehouse

ZhongyunTech is proud of its own 15 well-trained and experienced After-Sales Service Engineers, who are providing timely technical support for our customers around the world, day and night. Most of our After-Sales Service Engineers are graduated with mechanical/electrical bachelor degree. And 70% of them have over 10 years professional experience.

24-hour on call, Customers can get in-time service from ZhongyunTech to fix any of their issues.

Our warehouse dedicated for spare parts is 6000m2. With advanced ERP materials management system, the warehouse can quickly and accurately deliver necessary spare parts to our customers. Less downtime means more output.

We allocate exclusive service engineer to you immediately after signed contract, A regular on-site inspection will be done every year to prevent problems of the machine in your production.

Installation and commissioning of the ZhongyunTech corrugated pipe machines worldwide

Training of customers' technicians on how to use and maintain the corrugated pipe machines.

Trouble-shooting by phone, by Internet or on the site.

General overhaul of corrugated pipe extrusion line

Relocation of the machines

Upgrade the machines at customer factory

Regular Inspection to the corrugated pipe machines

More than 750 sets of corrugated pipe lines installed in more than 57 countries around the world.

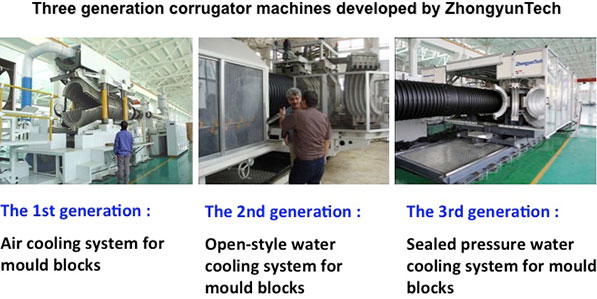

Developed all three generations of corrugators.

The FIRST corrugator machine in China with mould block parking station is made by ZhongyunTech.

The FIRST “High Speed Water Cooling” corrugated pipe production line in China is made by ZhongyunTech in 2009.

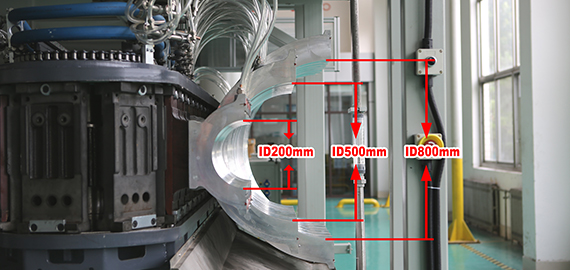

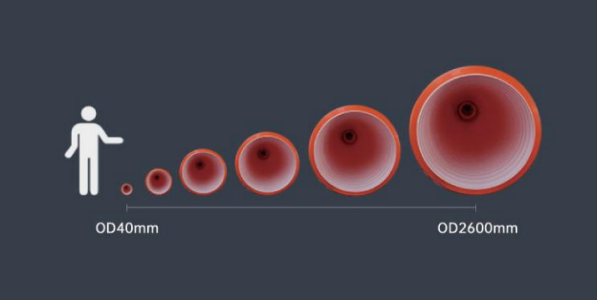

The corrugated pipe machines can cover from OD40mm to OD2600mm.

There are two corrugator lines running in China that can produce corrugated pipes up to OD2000mm. Both of them are manufactured by ZhongyunTech.

Sign up for our bimonthly newsletter

Privacy Policy- I have read and I authorize the processing of my personal data